During our webinar titled “Food Safety Culture and Color-Coding: How to exceed compliance and simplify complexities,†industry leaders shared insights on how simple tools like color-coding can help employees consistently follow food safety practices and foster a culture of producing safe, high-quality food.

Amit M. Kheradia, our environmental health and sanitation manager, and Lone Jespersen, Principal and Founder of Cultivate SA, answered questions during and after the session. Here are six key takeaways from their discussion.

1. Is there a formal science-based tool or supporting literature that helps evaluate food safety culture in an organization? What are some common measurable Key Performance Indicators (KPIs)?

According to the GFSI Technical Working Group, food safety culture is defined as “shared values, beliefs, and norms that affect mindset and behavior toward food safety across an organization.†While it's more abstract than technical standards like temperature controls or chemical concentrations, it can still be measured through performance indicators.

Some KPIs include:

- Employee hygiene and health practices

- Sanitation expectations and adherence

- Proper storage and handling protocols

- Cross-contamination prevention assessments

- Documentation and recordkeeping activities

Management must be committed to continuous improvement, forming a guiding team and empowering employees to take ownership. Resources such as the Cultivate Maturity Model, global standards like BRCGS, SQF, and FSSC 22000, and the PAS 320:2023 Guide can support this effort.

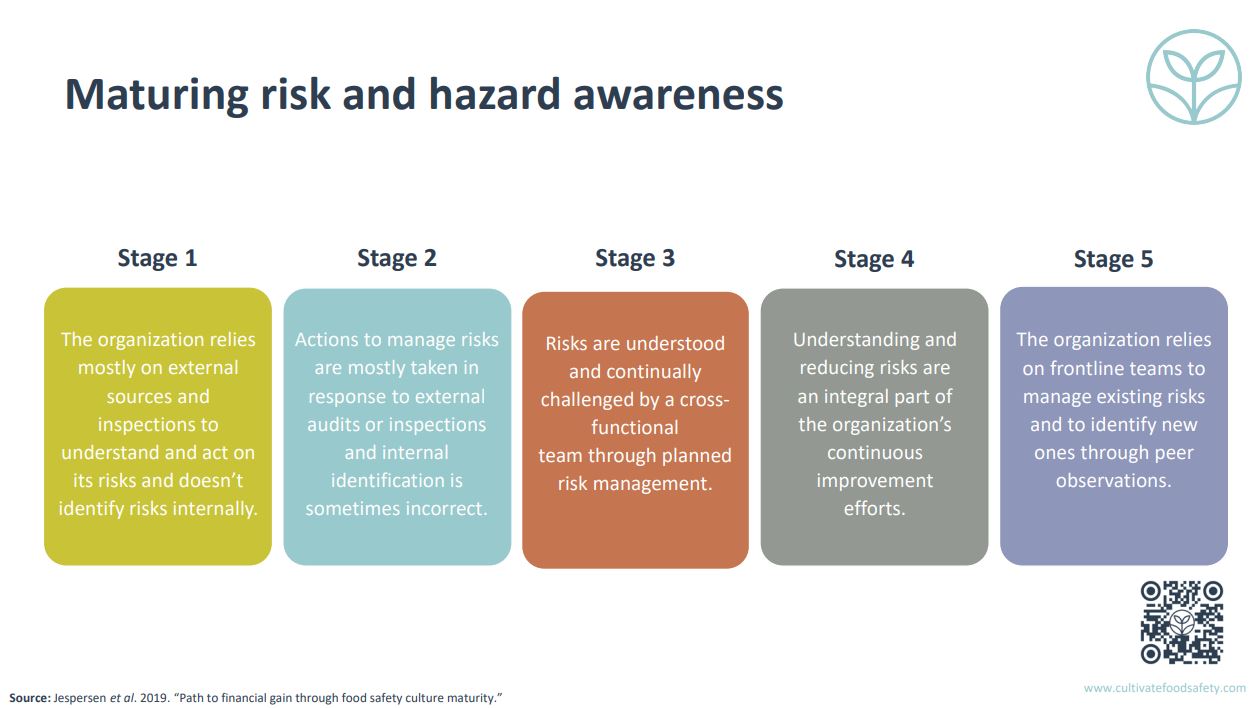

Color-coding plays a crucial role in simplifying complex food safety procedures by creating clear visual cues. As explained by Lone Jespersen, color-coding supports behavioral change by aligning with the stages of the Cultivate SA Food Safety Culture Maturity Model. In Stage 3, awareness of risks increases, and in Stage 4, staff begin applying these concepts practically. The ultimate goal is Stage 5, where food safety becomes a deeply embedded part of the organizational culture.

Practical examples of effective color-coding include:

- Color-coded uniforms for high-risk areas

- Color-coded containers for waste and products

- Zone-specific equipment and tools

- Color-coded labels for allergens

- Facility maps highlighting hygienic zones

Implementing color-coding requires training, consistent communication, and ongoing review to ensure employee engagement and understanding.

For more information, check out our Vikan’s Guide to Color-Coding.

3. Are there globally accepted color-coding standards for the food industry?

Vikan pioneered color-coding in the 1990s, and while it's now widely used, there's no single global standard. Organizations should tailor their plans based on site-specific needs, resources, and goals. However, we provide recommendations and guides, including our Vikan’s Guide to Color-Coding, to help you develop an effective system.

4. Why is a color-coding plan not enough to improve food safety culture?

Color-coding is just one piece of the puzzle. A mature food safety culture requires strong leadership, risk analysis, and consistent communication. It also involves reinforcing positive behaviors, setting clear expectations, and creating recognition programs that motivate employees at all levels.

5. How can companies recognize and reward employees to sustain food safety culture?

Recognition should be meaningful and aligned with what motivates individuals. It's important to involve frontline workers and HR in designing a program that rewards specific behaviors. Team-based recognition encourages collaboration and reinforces that food safety is a collective responsibility.

6. What tips can help develop a robust color-coding plan?

Keep it simple, consistent, and well communicated. Use tools like the Cultivate Maturity Model and integrate it into your behavior-based food safety system. Additional resources include white papers, guides, and checklists available on our website.

Disclaimer: The responses provided here are the professional opinions of the experts involved and do not necessarily reflect endorsements of any products or services mentioned. Companies should conduct their own risk assessments and develop custom solutions.

Recent blog posts

Digital solutions for a sustainable future

Digital tools like Virtual Site Surveys helped solve challenges during the pandemic and offer long-term benefits, including reducing environmental impact. This article explores how technology can support sustainability efforts in food production.

Essentials of Drain Sanitation for Food Production Facilities

Drains can be a major source of contamination if not properly managed. This post covers best practices for maintaining clean and safe drain systems in food facilities.

Key Proceedings of IAFP 2023 – Hot Topics in Global Food Safety

This summary highlights the most important discussions and innovations shared at the IAFP 2023 conference, offering valuable insights for food safety professionals worldwide.

Pastry Tools,Baking Tools,Cake Decorating Tools,Cake Decorating Kit

Xiongyang Household Co., Ltd , https://www.yjkitchen-manage.com